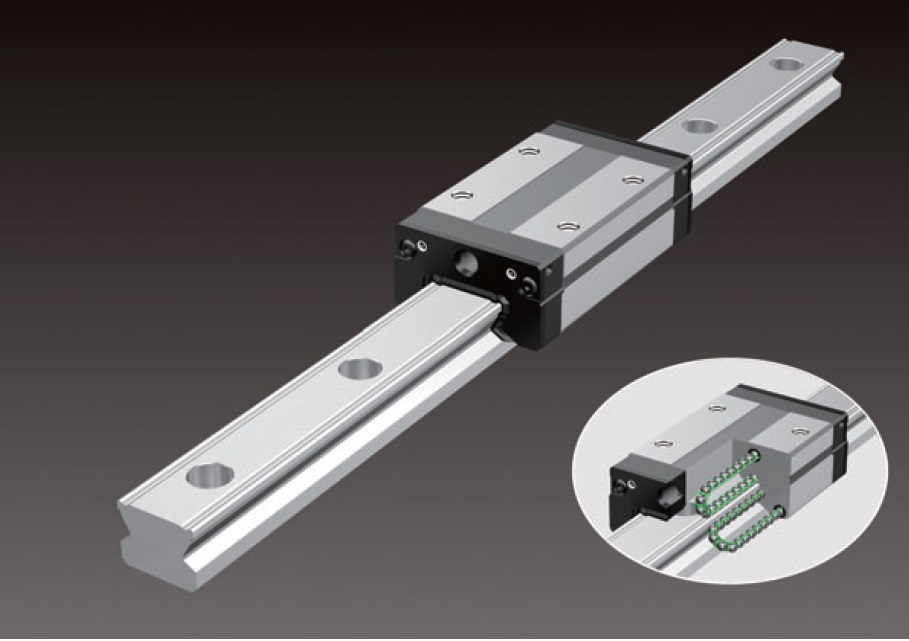

LM guide SSR is really a type of linear motion guide that features a bearing Cage. It is ideally designed to facilitate seamless and precise movement of your machine parts along this linear path. You need to know that the technology is generally used in industries like manufacturing automation and robotics, where accurate and reliable motion control is very important for the proper functioning of equipment and machinery. In this guide, you can learn everything about Bearing cage LM Guide SSR ( รังลูกปืน LM Guide SSR, which is also a term in Thai) and why it plays a crucial role.

The Functioning Of The Bearing Cage

The bearing cage in the LM guide works like a critical element that houses and separates the individual parts like balls or rollers. Additionally, it ensures that the proper alignment and distribution of the rolling elements allow them to move seamlessly along the Raceway. It helps you reduce friction and also improves the overall efficiency of the linear motion.

Benefits Of LM Guide SSR

· Better Durability

The bearing cage will provide you with all the structural support and stability of the rolling elements. It will help you minimize the wear and tear and also extend the overall lifespan of the guide.

· Smooth And Precise Motion

With the right guidance and separation provided by the bearing cage, the rolling elements can make it very easy for it to move along the Raceway. This means that you have to go through minimum wear and tear. It contributes towards the efficient operation of your machinery.

· Load Distribution

By evenly distributing all the load across the rolling elements, the bearing cage will ensure that the force or the weight exerted on the LM guide is managed well. It will help in preventing any excessive stress on the individual parts. It promotes A balanced and stable linear motion

· Maintenance And Care

Regular maintenance is very important to ensure the right performance and longevity of your bearing guide. This includes periodic cleaning to remove all the debris or contaminants which might impact the smooth movement. Furthermore, you need to properly lubricate the bearing cage and the Raceway to reduce friction and prevent any premature wear and tear.

Above all, you need to know that the bearing cage is a fundamental part of any mechanical system, facilitating seamless and accurate linear motion. It has a strong design and efficient load distribution property that makes it a great technology in the world of industrial automation.