You’re probably staring at a design, a problem, or a half-finished project, and the solution you keep circling back to is a material that seems both incredibly simple and bewilderingly complex. It’s not a high-tech polymer or a futuristic composite, it’s the humble, yet utterly indispensable, woven wire mesh. It’s the unsung hero in thousands of applications, from the filter in your coffee maker to the massive screen in a mining operation. But here’s the catch: just saying “I need some woven wire mesh” is like saying “I need a vehicle.” Are you going to the grocery store or competing in the Monaco Grand Prix? The devil, as they say, is in the details. Choosing the perfect woven wire mesh isn’t about grabbing the first sample you see, it’s a conversation between your project’s demands and the mesh’s characteristics. Let’s break down that conversation, so you can walk away confident you’ve made the right choice.

So, what exactly is this material we’re talking about? At its heart, woven wire mesh is precisely what it sounds like: individual wires, much like threads in a fabric, woven together on industrial looms. But this isn’t your grandmother’s knitting. This is a precise, engineered product where the interplay of the wires creates a grid of incredible strength and consistency. Think of it as a metallic tapestry, where the pattern, the thread thickness, and the material itself all combine to define its personality. The fundamental identity of any piece of woven wire mesh is locked in its weave pattern and the materials used. This is the foundation upon which everything else is built.

The Weave is the Way

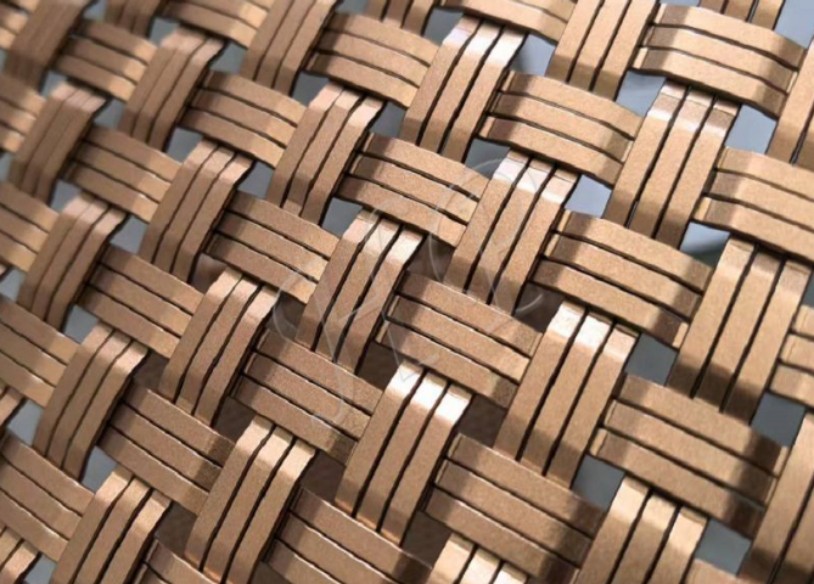

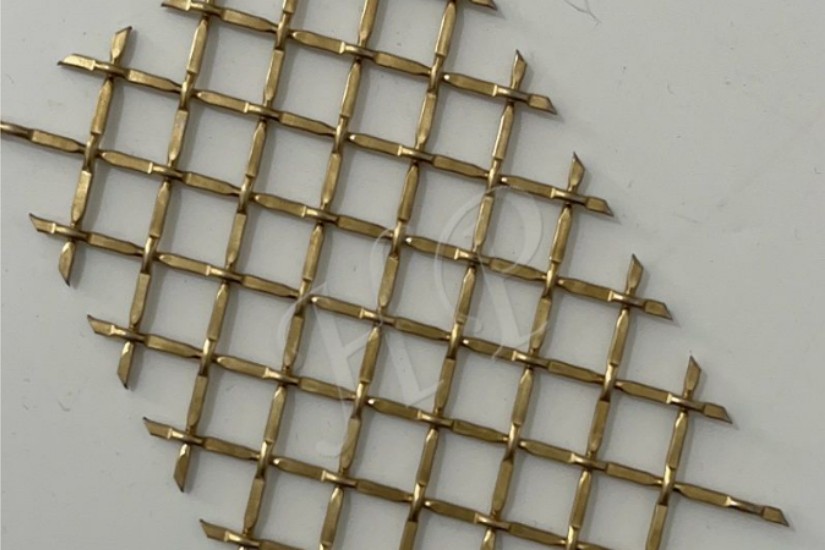

The pattern, or weave, is the first critical decision. It dictates not just what the mesh looks like, but how it behaves under stress, how fluids or light pass through it, and how it feels to the touch. The most common player in the game is the Plain Weave. This is the over-under, one-over-one pattern you instinctively imagine. It’s simple, strong, and cost-effective. If your job involves straightforward filtering, sizing, or shielding, this is your go-to woven wire mesh. It’s the reliable workhorse, predictable and robust. Then you have the Twilled Weave. Here, each wire passes over two and under two. This creates a distinctive diagonal pattern that isn’t just for looks. This structure allows for the use of heavier wires, creating a stronger, more durable mesh that still maintains a good level of open area. If you’re dealing with heavier loads or more abrasive materials, a twilled woven wire mesh might be your champion. For the ultimate in filtration finesse, you enter the realm of the Dutch Weave. This one is clever. It uses a system of thick warp wires and thinner weft wires, woven tightly together to create a mesh with no straight-through paths. It’s designed for filtering extremely fine particles out of liquids and gases under pressure. Choosing the right weave is like choosing the right stitch for a garment, the wrong one, and the whole thing falls apart under pressure.

It’s All in the Material

Once you’ve got a handle on the weave, you need to think about what the mesh is made of. This isn’t just about corrosion resistance, it’s about temperature, magnetism, strength, and even food safety. The king of the hill is Stainless Steel. Grades like 304 and 316 are the superstars here, offering a fantastic balance of corrosion resistance, strength, and affordability. If your woven wire mesh will see moisture, mild chemicals, or needs to be easy to clean, stainless steel is a safe bet. But if you’re by the ocean or dealing with more aggressive chlorides, you might need to upgrade to 316 for its molybdenum-enhanced defenses. For the purists and the high-temperature heroes, there’s Monel. This nickel-copper alloy is a beast against corrosive attack, especially from saltwater and acids. It’s also strong and maintains that strength at high temperatures, making it a favorite in demanding marine and chemical processing applications. And let’s not forget other members of the team, like Brass, with its good corrosion resistance and attractive appearance for decorative uses, or Copper, which is naturally antimicrobial and highly conductive. Picking the wrong material is a surefire way to watch your carefully selected woven wire mesh turn into a rusty, brittle failure long before its time.

Now, let’s get into the real engineering—the numbers that make your specific application tick. This is where you move from general concepts to the precise specifications that will make your project sing. It can feel a bit like learning a new language, with terms like “mesh count” and “wire diameter” being thrown around, but mastering this vocabulary is the key to unlocking the perfect performance from your woven wire mesh.

The Mesh Count and Wire Diameter Tango

Mesh count and wire diameter are the dance partners that define the very soul of your screen or filter. The mesh count simply refers to the number of openings per linear inch. A higher mesh count means more openings, which generally means smaller holes. A 100-mesh screen has 100 openings per inch, making it great for filtering out very fine particles. A 10-mesh screen has far fewer, larger openings, ideal for sifting coarse aggregates or providing structural support. But you can’t have mesh count without its partner, wire diameter. This is the thickness of the individual wires being woven. A thicker wire makes for a stronger, more durable woven wire mesh, but it also reduces the size of the openings for a given mesh count. This relationship is crucial. You could have two screens, both called 50-mesh, but one with a thin wire will have larger, more open pores, while one with a thick wire will be stronger but have less open area. This is the balance you must strike. Do you need maximum flow, or maximum strength? Understanding this tango between count and diameter is the first step to specifying the exact woven wire mesh your project requires.

Open Area and Filtering Performance

This leads us directly to a concept called ‘open area.’ This is the percentage of the total surface area of the woven wire mesh that is made up of open space, the holes themselves. It’s a critical number for any application involving the flow of air, liquid, or light. A mesh with a high open area will have less resistance to flow, allowing gases or liquids to pass through more easily. This is vital for efficiency in filtration systems, for example. If your open area is too low, you’re essentially asking your pump to work harder to push material through a smaller window, increasing energy costs and potentially causing backups. Calculating the open area involves both the mesh count and the wire diameter, and it’s a non-negotiable spec for filtration-centric projects. You can’t just guess at this, you need to know the numbers for your specific woven wire mesh selection to ensure it performs as needed, not just as hoped.

Alright, you’ve navigated the specs. You know you need a plain weave, 80-mesh, stainless steel 316 woven wire mesh with a 0.0055″ wire diameter. Fantastic. But the job isn’t done. How is this meticulously chosen material going to integrate into your real-world application? This is where we cross the bridge from theory to practice, considering the environment and the physical demands your mesh will face.

The Environment is Everything

Where your woven wire mesh will live its life is perhaps the most important long-term consideration. Is it sitting in a gentle airflow, or is it submerged in a vat of acidic chemicals? Is it facing constant abrasion from rocks and sand, or is it in a sterile food processing line? Each of these environments screams for a different solution. For high-temperature applications, like furnace curtains or heat-treating baskets, your standard 304 stainless might start to lose its strength, you might need to look at a 309 or 310 grade. For that abrasive mining environment, a heavier wire diameter and a twill weave will provide the longevity a plain weave can’t. If you’re in food and pharma, the surface finish of the woven wire mesh is paramount, it might need to be electropolished to a mirror finish to prevent bacteria from finding a home in microscopic surface imperfections. Ignoring the operating environment is the fastest way to turn a precision component into a costly mistake.

Strength and Stability Under Pressure

Finally, you have to think about the physical forces. Will your woven wire mesh be a static filter, or will it be vibrating vigorously in a screening machine? Is it a simple guard, or is it a structural element supporting significant weight? This dictates the need for additional support and the overall stability of the weave itself. A large, fine woven wire mesh panel will sag under its own weight if not properly supported by a underlying grid or frame. Understanding the tension, compression, and vibrational forces allows you to specify not just the mesh, but the necessary reinforcements—like thicker border wires or a specific type of edge preparation—to ensure it survives and thrives in its job. The mesh itself might be perfect, but if it’s not installed and supported correctly, its performance will be compromised.

Choosing the right woven wire mesh is a journey of matching a multitude of variables to a single, well-defined goal. It’s a process that rewards a little bit of homework and a lot of attention to detail. By understanding the conversation between weave, material, specification, and application, you stop being just a buyer and become a designer. You transform a generic material into a custom-tailored solution. So, the next time you face that project requirement, don’t just ask for woven wire mesh. Ask the right questions, define the parameters, and you’ll find that this incredibly versatile material is ready to deliver exactly what you need.